Manufacturing Capabilities in Numbers

Let our substantial production numbers be a testament to our strength as a reliable manufacturer of quality porcelain tableware.

Highlights in Manufacturing Process

Take a first-hand look at how PITO creates porcelain tableware, from the raw material processing to firing the completed products.

Make a Mold

Sample mold are created through sketches, plaster carving, clay sculpting, or digital modeling. High-quality plaster is then used to produce the final production molds.

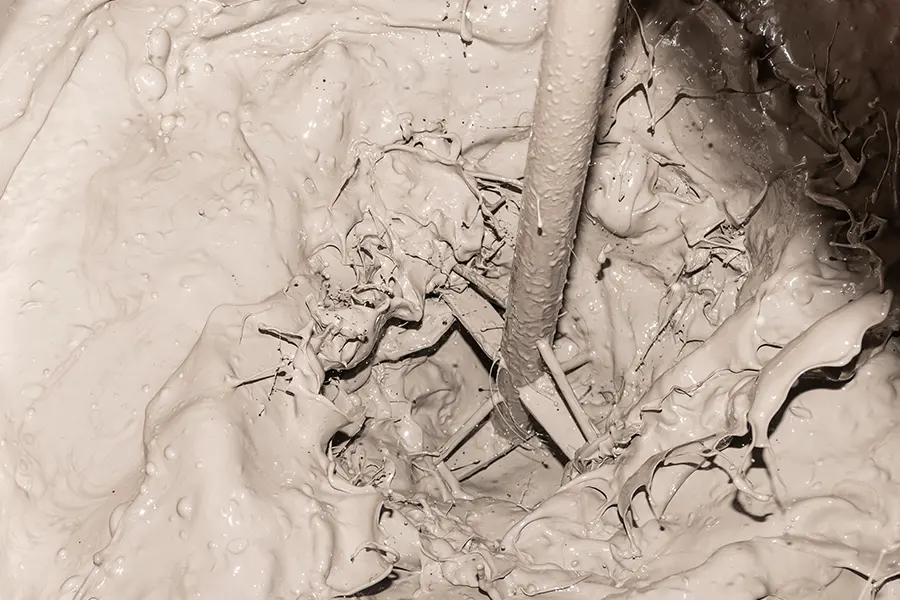

Refining Mud

Examination of raw material -batching-grinding - iron removal-filter-according to different shape use different pile of mud dehydration forming

Molding

Three methods are adopted: rolling forming, high pressure forming, grouting molding

Bisque-firing (First Firing)

The bisque firing takes place in the kiln at temperatures ranging from 1300°C to 1320°C. After firing, each bisque body undergoes a strict quality inspection, and only those that meet PITO standards are selected for the next stage.

Glazing

Before firing the porcelain tableware, we place a glaze covering on each to provide a distinct finish. Choose between manual or automatic spraying based on product shape. Spray evenly using a spray gun.

Glaze Firing (Second Firing)

Following foot wiping, the bisque pieces undergo a second firing — the glaze firing. Glaze firing temperature at 1280℃ for 8 hours.

Applique

Develop Decal design according to customer requirements. Divided into on-glaze decals / glazed Decal/ under-glaze decal. Then enter the kiln to fire decals according to the required temperature.

Decal Firing

According to decal temperature adjust the Decal firing temperature by computer (on-glaze temperature is 700-900 degrees). It takes 1 day to inspect the decal finished products

Recheck Details, Packaging, Shipping

Packaging and shipping according to customer requirements (use safe packing because the ceramic product is fragile). Packaging methods include air freight packaging, plywood racks, plywood pallets, plastic pallets, etc.

Selected Materials

PITO understands that our products are only as good as the materials used in production. To ensure the quality and durability of the porcelain tableware, we get our materials from the best sources in the market, including ceramic glazes from Japan and liquid gold from Germany.

Strict Quality Control

We practice strict quality control protocols throughout the production process. Handled by a dedicated inspection department with experience ranging from five to ten years, they conduct continuous product testing and send products to third-party labs for test reports upon request.