Porcelain manufacturing is a long-standing traditional craft in China that has experienced thousands of years of development and evolution. As one of the oldest and most exquisite ceramic making techniques in the world, porcelain manufacturing is deeply loved and appreciated by people for its unique craftsmanship and aesthetic value.

This blog will delve into the history, craftsmanship and artistic charm of porcelain manufacturing.

Historical origins of porcelain manufacturing

source: pinterest

Porcelain manufacturing originated in China, dating back thousands of years to the Neolithic Age. The ancient Chinese discovered the method of making pottery and continued to upgrade the technology, eventually creating a unique porcelain making process.

From the bronzes of the Shang Dynasty to the celadon of the Han Dynasty, to the blue and white porcelain and Jingdezhen porcelain of the Tang and Song Dynasties, the history of porcelain manufacturing has gone through many stages of development and evolution.

Characteristics of ancient porcelain making techniques

The ancient porcelain production process was mainly manual, including selecting porcelain clay, making the body, glazing, decoration and firing,etc.

Among them, making the adobe body is one of the key steps. It requires mixing porcelain clay with water, filtering it, and then kneading it into the desired shape.

Glazing is to glaze the adobe body to increase the luster and decorative effect of the porcelain. Finally, after firing at high temperatures, the porcelain production is finished.

The artistic charm of porcelain manufacturing

source: PITO bone china product

Porcelain manufacturing is not only a technical activity, but also an art. Through various decorative techniques and patterns, porcelain can display unique beauty and aesthetic value. Jingdezhen porcelain is famous for its exquisite blue and white techniques and delicate patterns, which fascinated people.

The production process of porcelain also requires craftsmen’s precise control of materials, pigments and heat, which fully reflects the ingenious combination of people and art.

Innovation and development of modern porcelain manufacturing

With the advancement of science and technology,also the improvement of craftsmanship, modern porcelain manufacturing has ushered in new development opportunities. The combination of traditional handcrafting and modern mechanized production makes porcelain manufacturing more efficient and precise. The application of new types of porcelain clay and glazes has improved the quality and features of porcelain.

At the same time, artists have also added more creativity and expression to the production of porcelain, making porcelain not only practical, but also artistic and collectible.

Application of modern technology in porcelain manufacturing

source: PITO factory

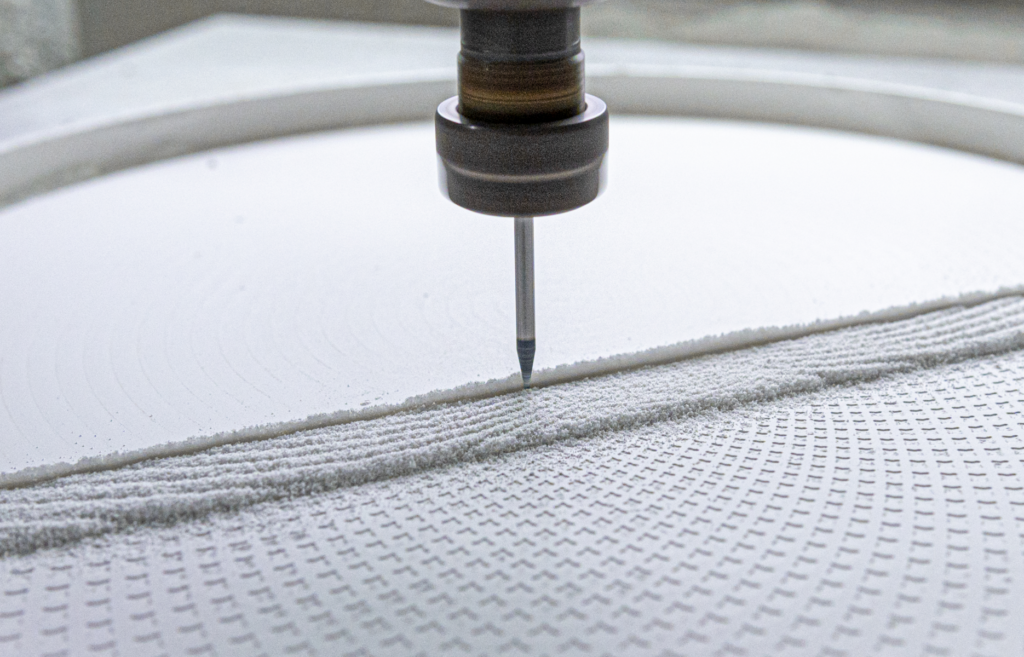

Modern technology has brought many new technologies to porcelain manufacturing, such as 3D printing technology, CNC machine tools, etc. The application of these technologies makes the production of porcelain more precise and efficient.

source: PITO factory

At the same time, technology also provides more possibilities for the design and decoration of porcelain, such as digital pattern design and laser engraving technology.

Innovative designs and trends in porcelain manufacturing

In modern society, porcelain manufacturing is experiencing repeated innovations and trends. Artists constantly try new design concepts and decorative styles, giving porcelain new vitality.

Meanwhile, porcelain also incorporates contemporary fashion elements to meet people’s diverse aesthetic needs.

The future of porcelain manufacturing

As one of the representatives of traditional crafts, porcelain manufacturing has rich cultural connotation and artistic value. With the progress of society and people’s pursuit of beauty, porcelain manufacturing still has broad room for development.

In the future, porcelain manufacturing will continue to blend traditional and modern elements to create more exquisite and high-quality works. At the same time, porcelain manufacturing will also move to the international stage to showcase China’s unique ceramic culture to people around the world.

Inheriting and protecting porcelain manufacturing techniques

It is crucial to inherit and protect porcelain manufacturing techniques. Relevant institutions and organizations should strengthen the protection and training of traditional crafts to ensure that traditional porcelain manufacturing skills can be inherited and developed.

Market prospects and application fields of porcelain manufacturing

Porcelain making is not only an art form but also an industry. With the increasing porcelain love and demands by people, the porcelain market has broad prospects.

In addition to daily use, porcelain is also widely used in interior decoration, gifts, art and other fields, providing new opportunities for economic development.

As a traditional Chinese craft for thousands of years, porcelain manufacturing embodies the wisdom and efforts of countless craftsmen. It is not only a technology, but also an art, showing the unique cultural charm of China.

Conclusion

With the advancement of science and technology and the promotion of innovation, porcelain manufacturing is radiating new vigor and vitality. Let us cherish and inherit this precious cultural heritage of porcelain manufacturing, and contribute to its development and dissemination.