Take a tour to the PITO ceramic crockery factory, and see how our premium products are made step by step.

Let our substantial production numbers be a testament to our strength as a reliable manufacturer of quality porcelain tableware.

Take a first-hand look at how PITO creates porcelain tableware, from the raw material processing to firing the completed products.

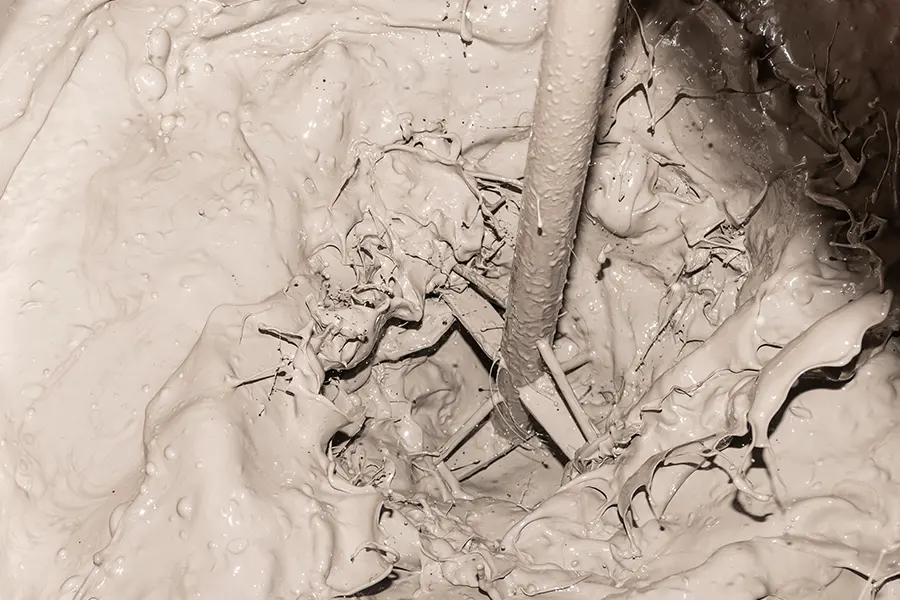

Using powerful crushers and mills, the carefully selected raw materials are ground several times to achieve the perfect consistency.

The crushed materials pass through a series of screens and filters, then mixed with water to create the slurry for the tableware.

Depending on the tableware type we’re making, we use one of four forming methods, including soft plastic forming, stiff plastic forming, pressing, and slip casting.

Once the tableware is formed, they are heated at a lower temperature to remove potential contaminants and reduce possible shrinkage when fired.

Before firing the porcelain tableware, we place a glaze covering on each to provide a distinct finish.

Our porcelain tableware enters the kiln and is baked at 1320°C, improving the hardness and increasing the service life of the completed product.

PITO understands that our products are only as good as the materials used in production. To ensure the quality and durability of the porcelain tableware, we get our materials from the best sources in the market, including ceramic glazes from Japan and liquid gold from Germany.

We practice strict quality control protocols throughout the production process. Handled by a dedicated inspection department with experience ranging from five to ten years, they conduct continuous product testing and send products to third-party labs for test reports upon request.

Elevate your brand with exceptional ceramic crockery with PITO. Talk to our team today and get started!

With 20 years of industry experience, PITO would like to be the humble craftsman of high-quality porcelain & Bone China dinnerware for you.

Contact us through our Contact Page Or email us at tableware@pitochina.com

© PITO 2025. ALL RIGHTS RESERVED.